Human 3D cell models for testing drugs

Deeptech

Laboratory equipment

Client: Lifetaq

Project

description

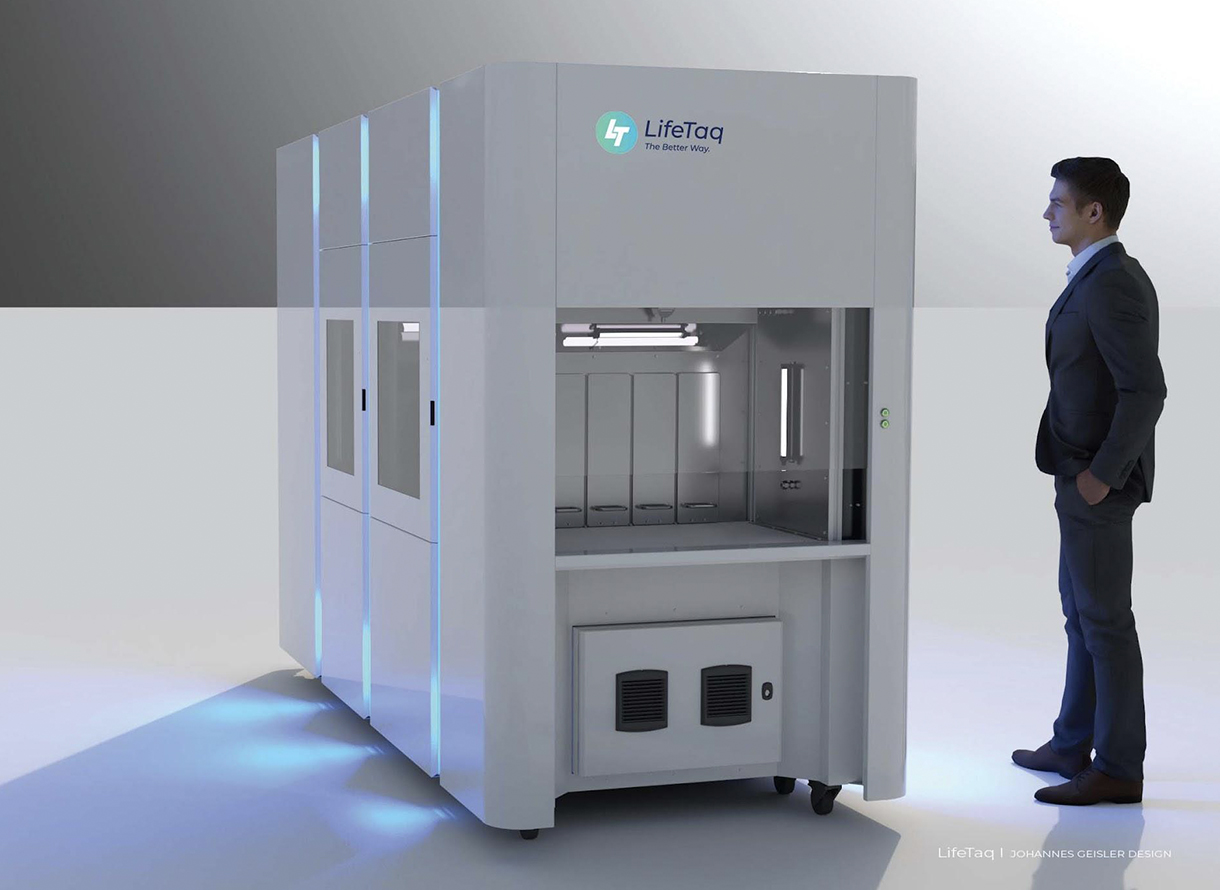

With its automated platform, Oli-MAT, LifeTaq cultivates human cells in a 3D in vitro environment that closely replicates their natural biological state. This enables more accurate predictions of the efficacy of drugs and therapies.

Together with the LifeTaq team and Johannes Geisler Design, we are working on the Oli-MAT and designing and assembling the housing for it.

Services

Product design

In our role as developers, we worked with industrial designer Johannes Geisler to come up with an innovative solution that enabled us to design the housing in an efficient and aesthetically appealing way, while taking into account pragmatic constraints in terms of cost and time. This close collaboration allowed us to create a design that combines functionality and high-quality aesthetics without exceeding the budget or time frame.

Prototype construction

Working closely with LifeTaq’s internal engineering team, we succeeded in developing a prototype that, thanks to the combined expertise and many years of experience of all those involved, could be transferred directly into the biotechnological testing process with virtually no adjustments. Thanks to structured coordination and continuous exchange within the team, an optimized development process was realized that maximized both the efficiency and quality of the prototype. This enabled us to facilitate a seamless transition to testing while ensuring that all functional and technical requirements were met right from the start.

Product development

Thanks to clearly defined responsibilities and our targeted focus on the housing of the biotech device, we were able to efficiently analyze several design proposals within a very short time. This provided LifeTaq with a sound basis for decision-making based on facts and practical aspects. Once the decision had been made, the housing was promptly and precisely converted into a CAD file ready for ordering, which enabled us to significantly accelerate the development process and pave the way for rapid production.

Production management

Thanks to clearly defined responsibilities and our targeted focus on the housing of the biotech device, we were able to efficiently analyze several design proposals within a very short time. This provided LifeTaq with a sound basis for decision-making based on facts and practical aspects. Once the decision had been made, the housing was promptly and precisely converted into a CAD file ready for ordering, which enabled us to significantly accelerate the development process and pave the way for rapid production.

3D design

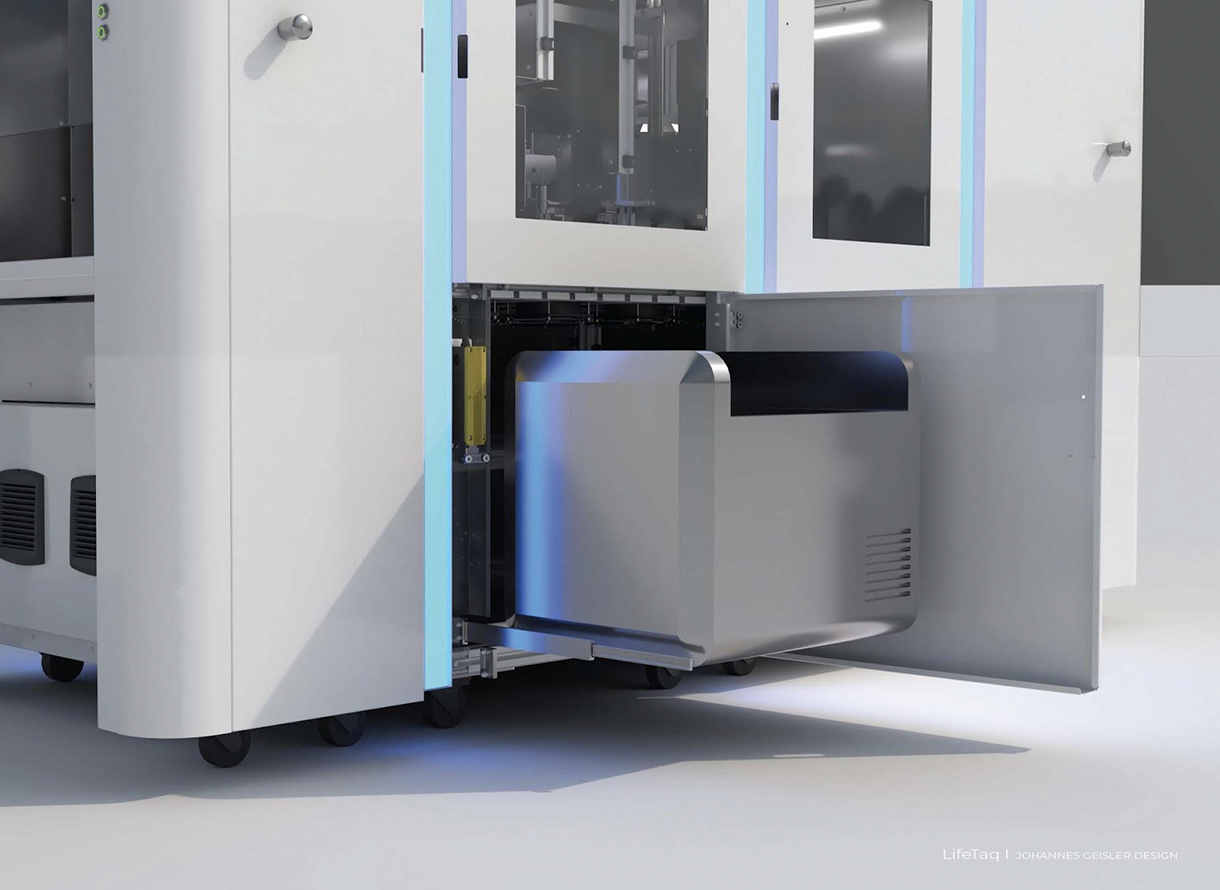

With a clear focus on the specific requirements for laboratory equipment and its materials, we worked with LifeTaq to develop practical solutions that provide users with optimal support in their everyday laboratory work and allow them to focus on what matters most. In no time at all, we created a CAD model of the sheet metal housing that was ready to order, supplemented by all the necessary data and workshop drawings required for a precise and straightforward inquiry to manufacturers.

4 separate modules, allowing for expandability to adapt to customer needs.

Fully automated system with two flow hoods to allow user intervention.

Various options for performing maintenance work via doors that are secured and sealed during the process.

Prototype, ready for commissioning and initial biotechnological testing.